High Tech Version |

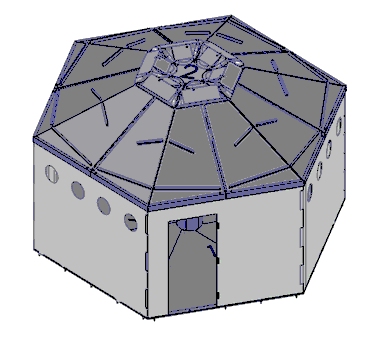

The high tech version, really the second version, would be constructed of high density polyetheylene plastic (HDPE). Although much more expensive than plywood, the HDPE version would last for 20 years. This is 15 years more than the requirements specify. It would be heavier and more expensive then plywood which would add to the logistical cost. |

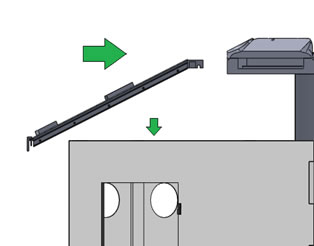

| The figure below shows a roof panel being inserted into the power cap and than onto a wall panel. In this version, stringers hold the wall and roof panels together. This interface would be very difficult to manufacture and was discarded. |

|

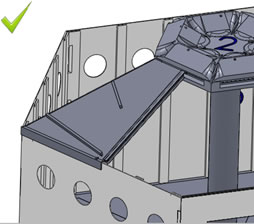

| Two roof panels are needed for each segment of the hexagon. Here you see a top view of one panel hooked into the power cap and latched onto a wall panel. The view below is an early version of the HOME Shelter. The latest version needs 2 4' x 6' plywood panels per hexagonal section. |

|

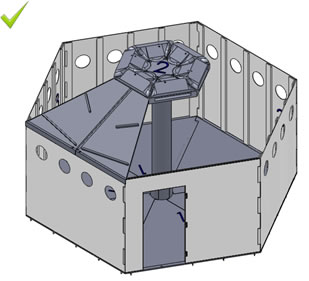

| The figure below shows what 2 roof panels look like interconnected. The latest version uses splines to interconnect wall and roof panels rather than stringers. |

|